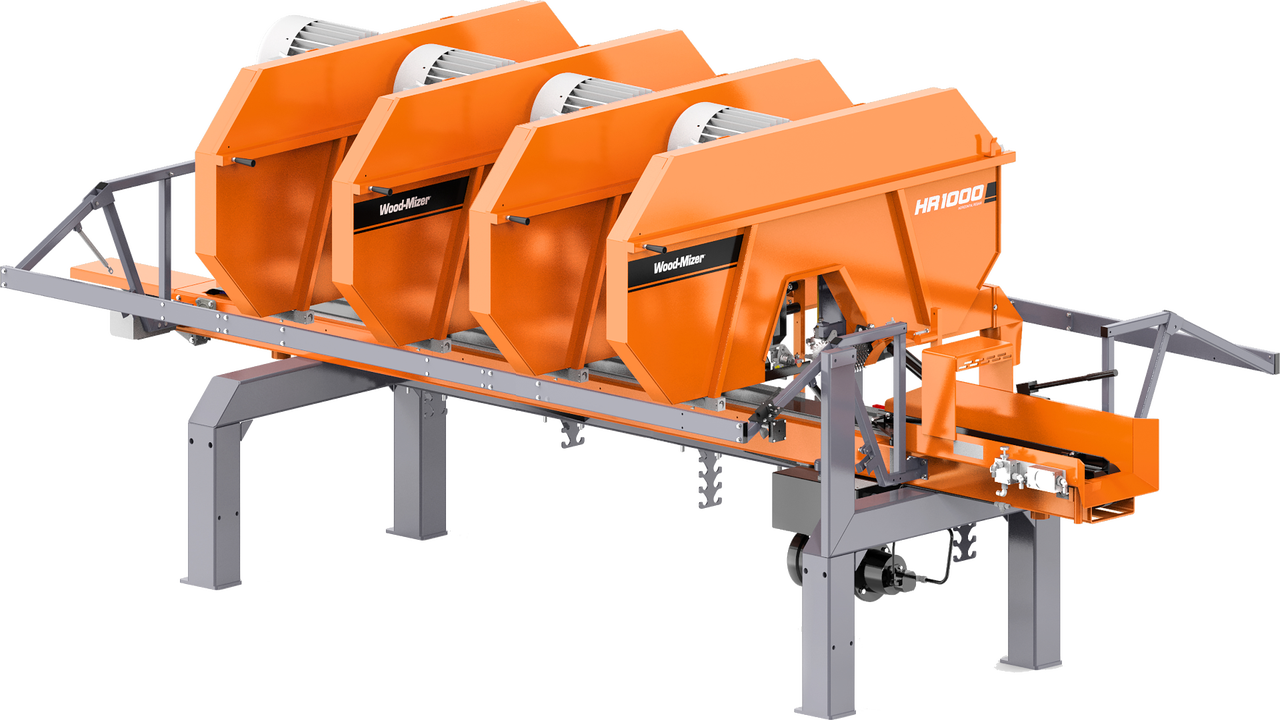

Description

Choose from one to six heads on this high-end resaw with potential to produce up to seven boards at once. This machine easily integrates into existing systems and has a small footprint so you can maximize your space. The powered hold-down rollers ensure tight tolerances for the most precise requirements. An optional Merry-Go-Round (MGR) system can be added to automate the entire process of breaking down larger cants.

Performance:

- Productive – saws up to seven boards in one pass using thin-kerf technology.

- Tough – tackles any species from frozen to kiln dried.

- Accurate – Steel track conveyor keeps cuts accurate.